Introduction

In the expansive field of heavy machinery, Hydra Cranes stand as robust and adaptable tools, earning their reputation for excellence in diverse lifting applications. This article embarks on a thorough exploration of Hydra Cranes, delving into the intricate details of their components, operational mechanisms, and applications.

Understanding Hydra Cranes: A Hydra Crane, short for Hydraulic Crane, is a sophisticated lifting apparatus that relies on hydraulic systems for controlled and precise movements. Widely recognized for their flexibility, Hydra Cranes find applications across various industries, ranging from construction to maintenance and beyond.

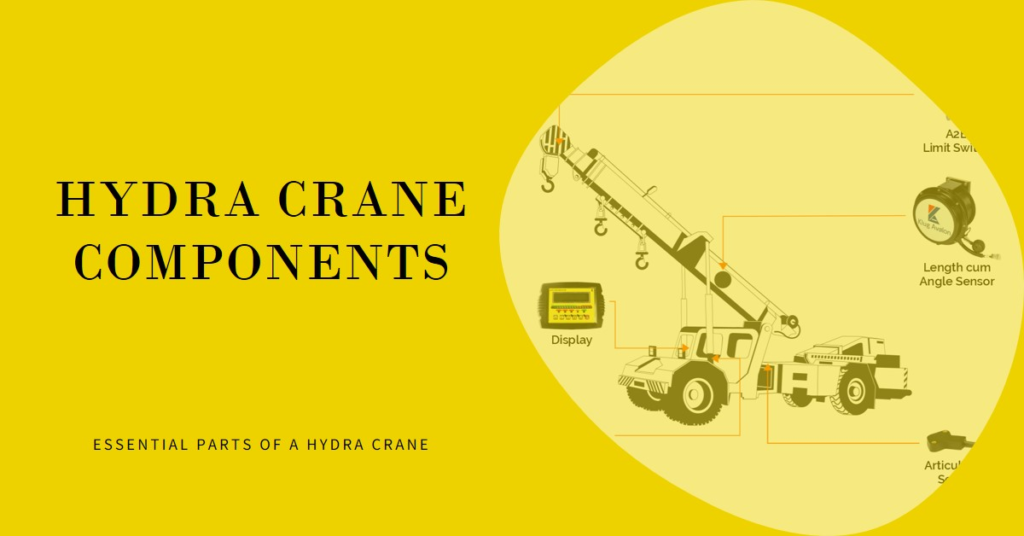

Key Components of a Hydra Crane

- Boom: The extendable arm of the crane, the boom, serves as the primary lifting mechanism, providing the crane with the necessary reach and capability to handle heavy loads.

- Hydraulic Cylinders: Positioned as the powerhouse, hydraulic cylinders utilize pressurized hydraulic fluid to control the crane’s movements, ensuring smooth and controlled operations.

- Outriggers: Vital for stability, outriggers are stabilizing legs that offer balance and support, particularly crucial when the crane operates on uneven or challenging terrain.

- Operator’s Cabin: Serving as the nerve center, the operator’s cabin houses controls that empower operators to manage the crane’s functions with precision, overseeing every aspect of the lifting process.

- Counterweights: Strategically placed counterweights play a pivotal role in preventing tipping during heavy lifts, contributing significantly to the overall stability and safety of the crane.

Operational Mechanism: The functionality of Hydra Cranes is rooted in hydraulic pressure. As operators manipulate controls, hydraulic fluid, typically oil, is pressurized in the cylinders. This pressurized fluid, in turn, activates hydraulic motors, orchestrating the coordinated movements of the crane’s components. The result is a seamless and efficient lifting process that distinguishes Hydra Cranes from their traditional counterparts.

Applications of Hydra Cranes

Hydra Cranes, owing to their versatility and robust design, find diverse applications across various industries. Their adaptability makes them indispensable in a wide range of scenarios, contributing significantly to the efficiency and effectiveness of lifting operations. Let’s delve into the detailed applications of Hydra Cranes:

- Construction Industry:

- Material Handling: One of the primary applications of Hydra Cranes in construction is the lifting and precise placement of heavy construction materials. This includes lifting steel beams, concrete slabs, and other components essential for building structures.

- Structural Erection: Hydra Cranes play a pivotal role in the erection of buildings, bridges, and other infrastructure. Their ability to extend the boom to great heights facilitates the positioning of structural elements with accuracy.

- Maintenance Operations:

- Heavy Machinery Installation: In industrial settings, Hydra Cranes are instrumental in the installation and removal of heavy machinery. This includes positioning equipment for maintenance or installing new machinery on factory floors.

- Plant Maintenance: Hydra Cranes are employed for maintenance tasks in power plants, refineries, and other industrial facilities, aiding in the repair and replacement of critical components.

- Loading and Unloading:

- Cargo Handling at Ports: At ports and harbors, Hydra Cranes are used for loading and unloading cargo from ships. Their adaptability and reach make them suitable for efficiently moving containers and other heavy loads.

- Logistics and Warehousing: In logistics and warehouse operations, Hydra Cranes are employed to load and unload goods from trucks, facilitating the seamless movement of materials within distribution centers.

- Emergency Response:

- Disaster Relief: During natural disasters or emergencies, Hydra Cranes are deployed for swift and precise lifting operations. They assist in tasks such as removing debris, rescuing people from inaccessible areas, and setting up temporary structures.

- Search and Rescue: The mobility of Hydra Cranes allows them to reach challenging terrains, making them valuable in search and rescue operations where heavy lifting is required.

- Infrastructure Development:

- Bridge Construction: Hydra Cranes contribute significantly to bridge construction, lifting and placing heavy components like girders and segments. Their ability to navigate challenging terrains and extend over water makes them vital in this application.

- Highway Projects: In the construction of highways and tunnels, Hydra Cranes assist in handling and placing large sections of concrete, steel, and other materials required for road infrastructure.

- Oil and Gas Industry:

- Drilling Rig Operations: Hydra Cranes are utilized in the oil and gas sector for lifting and positioning equipment on drilling rigs. Their robust design and lifting capacity make them suitable for the heavy-duty demands of offshore and onshore operations.

- Renewable Energy Projects:

- Wind Turbine Installation: In the renewable energy sector, Hydra Cranes play a role in the installation of wind turbines. They lift and position turbine components, including tower sections, nacelles, and blades, contributing to the growth of wind energy projects.

- Demolition Work:

- Building Demolition: Hydra Cranes are employed in controlled building demolition, where precision is crucial. They assist in lifting and lowering heavy debris, ensuring a safe and organized demolition process.

- Railway Infrastructure:

- Rail Track Maintenance: Hydra Cranes are used for maintenance and repair work on railway tracks. They assist in lifting and placing heavy rail sections, sleepers, and other components.

Advantages of Hydra Cranes

- Versatility:

- Diverse Lifting Tasks: Hydra Cranes stand out for their remarkable versatility in handling a myriad of lifting tasks. Whether it’s lifting heavy construction materials on a building site or delicate components in an industrial setting, these cranes effortlessly adapt to the unique demands of each job site.

- Adaptable Configurations: The crane’s design allows for easy customization and adaptation, enabling it to efficiently tackle a wide range of loads and spatial challenges.

- Efficiency:

- Precise Hydraulic Control: The heart of a Hydra Crane lies in its hydraulic system, providing operators with precise control over movements. This level of precision enhances operational efficiency, ensuring that lifts are not only smooth but also accurate.

- Reduced Manual Effort: The hydraulic system minimizes the need for manual effort, reducing the physical strain on operators. This results in more efficient operations, particularly during repetitive or extended lifting tasks.

- Mobility:

- Navigating Various Terrains: Mounted on wheels, Hydra Cranes exhibit exceptional mobility, capable of navigating through a variety of terrains. This feature is especially advantageous in construction projects where job sites may vary in accessibility and conditions.

- Transportability: The crane’s mobility extends beyond the job site. Hydra Cranes can be easily transported from one location to another, offering a level of flexibility that is particularly beneficial in industries requiring frequent shifts between project sites.

- Compact Design:

- Space Efficiency: Despite their considerable lifting power, Hydra Cranes maintain a relatively compact design. This feature makes them well-suited for operating in confined spaces where traditional cranes might struggle to maneuver. The ability to work in tight quarters enhances their utility in urban construction environments.

- Minimized Footprint: The compact design contributes to a minimized footprint on the job site, allowing for efficient use of available space without compromising on lifting capabilities.

- Quick Setup:

- Swift Deployment: The hydraulic systems integrated into Hydra Cranes facilitate a rapid and straightforward setup process. This quick deployment translates to minimized downtime on the job site, maximizing productivity.

- Optimized Workflow: The ability to set up swiftly is particularly advantageous in dynamic work environments where time efficiency is crucial. Hydra Cranes contribute to an optimized workflow, allowing for more focus on the task at hand and less time spent on equipment preparation.

Safety Considerations for Hydra Crane Operations

- Operator Training and Certification:

- Prioritize comprehensive training programs for operators, covering crane operations, safety protocols, and emergency procedures. Ensure operators hold necessary certifications, demonstrating proficiency and compliance with industry standards.

- Pre-Operation Inspections:

- Conduct meticulous pre-operation inspections, emphasizing routine maintenance checks to identify and address potential issues promptly. Maintain detailed documentation of inspections and maintenance activities to track the crane’s operational history.

- Load Capacity Awareness:

- Emphasize the importance of understanding load charts among operators. Provide clear guidelines to avoid overloading risks, ensuring operators accurately calculate loads and communicate effectively with other personnel involved in the lift.

- Site Planning and Risk Assessment:

- Before operations, conduct thorough site-specific planning. This includes a detailed analysis of ground conditions, overhead obstacles, and potential hazards. Perform a comprehensive risk assessment to mitigate risks associated with the lift.

- Communication Protocols:

- Establish clear communication channels between the crane operator and ground personnel. Utilize standardized hand signals or radio communication protocols to convey instructions effectively, particularly in scenarios with limited visibility.

- Weather Monitoring:

- Monitor weather conditions closely before and during crane operations. Suspend operations in the presence of adverse weather, such as high winds or storms, to mitigate risks associated with crane stability.

- Emergency Response Preparedness:

- Ensure operators are well-versed in emergency response procedures. This includes protocols for equipment malfunctions, accidents, or unexpected situations. A well-defined emergency plan enhances readiness to handle unforeseen events promptly.

- Personal Protective Equipment (PPE):

- Enforce the use of appropriate Personal Protective Equipment (PPE) for all personnel involved in crane operations. This includes hard hats, high-visibility clothing, gloves, and safety footwear to minimize the risk of injuries.

- Proximity to Power Lines:

- Exercise extreme caution when operating near power lines. Maintain safe distances to prevent electrical hazards. Operators should be acutely aware of the crane’s vertical and horizontal clearances from power lines.

- Continuous Training and Updates:

- Implement a program of regular refresher courses for operators. This ensures they stay abreast of new technologies, safety regulations, and best practices in Hydra Crane operations, fostering a culture of continuous learning and improvement.

MORE INFORMATION

Conclusion

In conclusion, Hydra Cranes emerge as indispensable giants in the heavy machinery landscape, offering a harmonious blend of versatility, efficiency, and mobility. A nuanced understanding of their components, operational mechanisms, and applications equips professionals in the construction and industrial sectors to harness the full potential of Hydra Cranes, ensuring their continued impact on shaping our world. As these machines continue to evolve, their significance in lifting and material handling operations is set to grow, making Hydra Cranes a cornerstone in the ever-advancing field of heavy machinery.

I have read some excellent stuff here Definitely value bookmarking for revisiting I wonder how much effort you put to make the sort of excellent informative website

Hi i think that i saw you visited my web site thus i came to Return the favore Im attempting to find things to enhance my siteI suppose its ok to use a few of your ideas

I do not even know how I ended up here but I thought this post was great I do not know who you are but certainly youre going to a famous blogger if you are not already Cheers

Thank you!!

I have read some excellent stuff here Definitely value bookmarking for revisiting I wonder how much effort you put to make the sort of excellent informative website

Thank you!!

I was suggested this web site by my cousin Im not sure whether this post is written by him as no one else know such detailed about my trouble You are incredible Thanks

Thank you so much for your kind words! I’m glad to hear that you found the information helpful. Whether your cousin recommended the website or not, I’m here to assist you with any questions or troubles you may have. Don’t hesitate to visit again if you need further assistance or if you have any more questions. We’re always here to help!

Hello Neat post Theres an issue together with your site in internet explorer would check this IE still is the marketplace chief and a large element of other folks will leave out your magnificent writing due to this problem

Thank you for bringing this to our attention. We apologize for any inconvenience you may be experiencing with our site in Internet Explorer. We’ll definitely look into this issue to ensure a smoother browsing experience for all users, including those using Internet Explorer. If you have any specific feedback or if there’s anything else we can assist you with, please feel free to let us know. We appreciate your understanding and patience.

Thanks I have just been looking for information about this subject for a long time and yours is the best Ive discovered till now However what in regards to the bottom line Are you certain in regards to the supply

Nice blog here Also your site loads up fast What host are you using Can I get your affiliate link to your host I wish my web site loaded up as quickly as yours lol

I’m glad to hear that you like the blog and find the site loading fast. We’re currently using Hostinger as our hosting provider. If you’re interested, you can use my affiliate link: [https://hostinger.in?REFERRALCODE=1NITIN633] to check out Hostinger. Let me know if you have any more questions or if there’s anything else I can assist you with!