Introduction

Welcome to our comprehensive guide on selecting the perfect Single Girder EOT Crane for your workshop. EOT (Electric Overhead Traveling) cranes are the unsung heroes of many workshops, warehouses, and manufacturing facilities. These remarkable machines make lifting heavy loads seem effortless, streamlining operations and enhancing workplace safety.

In this article, we’ll take you through the journey of choosing the right Single Girder EOT crane for your workshop. Whether you’re in manufacturing, automotive repairs, or any other industry that relies on heavy lifting, this guide is your roadmap to making an informed decision. By the end of this article, you’ll be equipped with the knowledge you need to not only find the right crane but also to maximize efficiency and safety in your workspace.

Table of Contents

Understanding Your Workshop Needs

The journey to choosing the perfect crane begins with understanding your workshop’s unique needs. Workshops are as diverse as the tasks they handle, and it’s essential to recognize the specific demands of your own. Whether you’re in a manufacturing plant, a construction site, or an automotive repair shop, each has its unique requirements.

Before diving into the nitty-gritty of crane types and specifications, take a step back and evaluate your workshop. What do you do? What materials or products do you need to lift and move? How often do you perform these tasks? Understanding these aspects is the foundation of making the right crane choice.

If you primarily handle manufacturing processes, your crane needs will differ from those of an auto repair shop that focuses on lifting vehicles for maintenance. By knowing precisely what your workshop does and what you need to lift, you’ll be better equipped to make an informed choice.

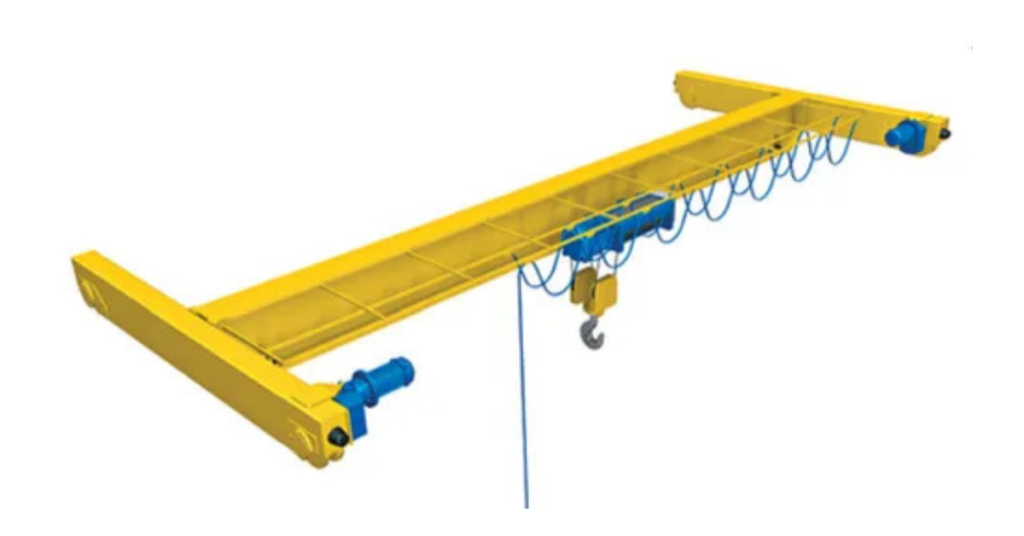

Types of Single Girder EOT Cranes

Now that you have a clearer picture of your workshop’s needs, it’s time to delve into the world of Single Girder EOT Cranes. These cranes are available in various configurations, each designed for specific use cases. Understanding these different forms is key to making the right choice for your workshop.

A. Top-Running Cranes: These cranes run on rails installed on the top of the building structure. They are suitable for heavy-duty lifting and are often used in manufacturing and industrial facilities.

B. Under-Running Cranes: Under-running cranes, as the name suggests, run on the bottom flanges of the runway beam. They are ideal for low-headroom applications and can save valuable vertical space.

C. Single Girder vs. Double Girder: In addition to the running style, you’ll need to decide whether a single girder or double girder crane suits your needs. Single girder cranes are lighter and more cost-effective, while double girder cranes offer higher load capacity and greater durability.

D. Box Girder vs. I-Beam Girder: The type of girder also matters. Box girders are more rigid and are a great choice for heavy loads, while I-beam girders are more cost-effective and versatile.

By understanding these variations, you can choose the crane that best aligns with your workshop’s specific requirements. This step ensures that your crane will not only lift effectively but also endure the test of time.

Weight and Load Considerations

An integral part of selecting the right crane is ensuring that it can handle the weight and size of the loads in your workshop. Without a doubt, this is a crucial aspect that shouldn’t be overlooked.

To get started, you’ll need to calculate the weight of the heaviest loads that your crane will need to lift. This could be machinery, raw materials, products, or any other items that require movement within your workshop. Once you have a good estimate of the maximum weight, add a safety margin to account for unexpected variations in load weight.

Next, consider the dimensions of the loads. Some items might be long, wide, or irregularly shaped. You’ll need a crane with an appropriate span and hook height to ensure that it can maneuver these loads safely. By doing these calculations and evaluations, you’ll ensure that the crane you choose can effectively and safely handle the specific lifting needs of your workshop.

MORE INFORMATION

Height and Space Constraints

Your workshop’s layout and space constraints are important factors in selecting the right Single Girder EOT crane. If your crane doesn’t fit comfortably and efficiently within your workspace, it can lead to costly disruptions and inefficiencies.

Start by assessing your workshop’s ceiling height. This will influence the height of the crane’s hook and the required headroom. The hook height should provide enough space to lift and transport loads without interfering with the ceiling.

Additionally, consider the available space on the workshop floor. Make sure the crane’s runway length and width fit your layout. For under-running cranes, evaluate the space needed for the crane’s travel path and how it aligns with your workstations and storage areas.

The goal is to have a crane that seamlessly integrates with your workshop’s physical constraints. An ill-fitting crane can lead to a cramped and unsafe workspace, which is something you’ll want to avoid.

Duty Cycle and Frequency of Use

How often and for what duration your crane will be in use is a critical factor in selecting the right crane. Single Girder EOT cranes come with duty cycle ratings, which classify them into categories such as light, moderate, and heavy-duty.

The duty cycle rating defines how frequently and for how long the crane can safely operate. It’s essential to match the crane’s duty cycle with your workshop’s actual usage. Here’s a breakdown:

A. Light Duty: These cranes are suitable for infrequent or occasional use, typically for lighter loads and tasks that don’t demand continuous operation.

B. Moderate Duty: These cranes are a middle ground, capable of handling more frequent use and moderate loads. They are often found in workshops that have a balance between light and heavy lifting requirements.

C. Heavy Duty: Heavy-duty cranes are designed for continuous and demanding use. They can handle heavy loads and operate for extended periods without overheating or wearing out.

Selecting the right duty cycle is vital to ensure the longevity and safety of your crane. Choosing a crane with a lower-duty cycle for a heavy-duty workshop, for instance, would result in frequent breakdowns and costly repairs.

Safety Features and Regulations

In any workshop, safety is paramount. The safety of your personnel and the integrity of your equipment are non-negotiable. Single Girder EOT cranes come equipped with a variety of safety features to help protect your team and your investments. Here’s what to look for:

A. Limit Switches: These switches prevent the hook or trolley from traveling beyond certain pre-set limits, preventing collisions with the crane’s structure or other objects.

B. Emergency Stop Button: An easily accessible emergency stop button allows for an immediate halt in crane operation in case of an emergency or any hazardous situation.

C. Overload Protection: This feature prevents the crane from lifting loads exceeding its rated capacity, protecting both the crane and the load.

D. Safety Audits and Compliance: Ensure that your crane complies with local safety regulations and standards. Regular safety audits and maintenance checks are essential to keep the crane in optimal condition.

Emphasize the importance of safety in your workshop. It’s not just about the features but also about how you and your team use the crane. Safety training and adherence to safety protocols are essential for a secure work environment.

In the world of EOT cranes, safety isn’t an option; it’s a necessity. By choosing a crane with the right safety features and ensuring that your workshop follows all safety guidelines and regulations, you’re taking a proactive step to protect your employees and your investment.

Budget and Cost Factors

Every workshop has a budget, and this is a significant factor when choosing a Single Girder EOT crane. The cost of a crane is not limited to its purchase price. You also need to consider installation, maintenance, and any additional accessories or modifications required.

Here’s what you should consider:

A. Initial Cost: This includes the cost of the crane itself. Single girder cranes are generally more cost-effective than double girder ones. The type of girder (box or I-beam) also affects the cost.

B. Installation Costs: You’ll need to install the crane, which may involve structural modifications to your workshop. Make sure you budget for these expenses.

C. Maintenance Costs: Regular maintenance is crucial for keeping your crane in optimal condition. Factor in the cost of maintenance and any spare parts that may be needed.

D. Long-Term Cost: Think about the overall cost of ownership, which includes not just the purchase price but also ongoing expenses.

Remember that while budget is essential, it shouldn’t be the sole deciding factor. A cheap crane that doesn’t meet your workshop’s needs can end up costing more in the long run due to repairs and inefficiencies. Balancing cost considerations with your workshop’s requirements is key.

Consulting with Experts

Choosing the right crane can be a complex task, and it often pays to seek advice from professionals in the field. Manufacturers, crane specialists, and engineers have extensive knowledge and experience. They can provide invaluable insights into what type of crane is best suited for your workshop’s needs.

The benefits of consulting with experts include:

A. Tailored Solutions: Experts can analyze your workshop’s specific requirements and recommend a crane configuration that aligns perfectly with your needs.

B. Compliance: They ensure that your crane complies with safety and industry standards, reducing the risk of accidents and costly fines.

C. Long-Term Reliability: Experts can guide you toward reliable crane manufacturers and models that have a proven track record. – Cost-Efficiency: They can help you make cost-effective decisions by avoiding over-specification or under-specification.

Don’t hesitate to reach out to crane professionals or manufacturers. Their expertise can make the selection process smoother and lead to a more informed decision. This is an acquisition that pays off in the long run. Case Studies and Real-World Examples

Learning from the experiences of others is a great way to gain insights into choosing the right Single Girder EOT crane for your workshop. Let’s explore some real-world examples and case studies to see how different workshops found the perfect crane solutions.

Case Study 1: Manufacturing Marvels

A medium-sized manufacturing workshop was in need of a crane to move heavy machinery and raw materials. They decided to go for a top-running single-girder EOT crane with a moderate-duty cycle. The crane’s ability to lift and move heavy loads streamlined their production process, and it fit perfectly into their high-ceiling facility.

Case Study 2: Auto Repair Shop Success

An auto repair shop required a crane for lifting vehicles during maintenance and repair work. Their space was limited, so they opted for an under-running single girder crane, which saved precious headroom. The crane’s compact design allowed them to efficiently lift cars without the need for extensive structural modifications.

These case studies illustrate that the choice of the right crane depends on the unique needs and constraints of each workshop. By examining these real-world examples, you can draw inspiration for your own workshop’s crane selection.

Conclusion

As we wrap up our journey through the process of selecting the ideal Single Girder EOT Crane for your workshop, let’s recap the key takeaways.

Choosing the right crane is not a one-size-fits-all endeavor. It’s a tailored decision that depends on your workshop’s unique needs. Understanding those needs is the first and most crucial step. Whether you’re in manufacturing, construction, automotive repair, or any other industry, the crane you select should align perfectly with what you do and what you need to lift.

Consider the type of crane, its weight and load capacity, height and space constraints, and the frequency of use. Safety is non-negotiable, so prioritize a crane with the necessary safety features and ensure compliance with regulations. Budget considerations are essential, but don’t sacrifice functionality and safety for cost savings.

Consulting with experts and learning from real-world examples can provide invaluable guidance on your crane selection journey. It’s an investment in your workshop’s efficiency and safety that pays dividends in the long run.

Closing Thoughts

In the grand scheme of things, selecting the right Single Girder EOT crane is an investment in your workshop’s efficiency and safety. It’s a decision that impacts your productivity, your bottom line, and the well-being of your team. Therefore, this is not a decision to be taken lightly or hastily.

We hope this guide has provided you with the insights and knowledge you need to make an informed choice. It’s a decision that should be made with careful consideration of your workshop’s unique needs, the safety of your team, and your long-term budget.

Don’t rush the decision. Take your time, do your research, and consult professionals. Find the crane that perfectly suits your workshop, and watch how it transforms the way you handle heavy loads. A well-chosen EOT crane isn’t just a piece of equipment; it’s a partner in your workshop’s success.

With the right crane in place, you’re on the path to enhanced efficiency, increased safety, and smoother operations. Good luck with your Single Girder EOT crane selection journey!

I loved you better than you would ever be able to express here. The picture is beautiful, and your wording is elegant; nonetheless, you read it in a short amount of time. I believe that you ought to give it another shot in the near future. If you make sure that this trek is safe, I will most likely try to do that again and again.

Nice blog here! Also your site loads up fast! What host are you using? Can I get your affiliate link to your host? I wish my web site loaded up as quickly as yours lol

Thank you!! https://hostinger.in?REFERRALCODE=1NITIN633

Somebody essentially help to make significantly articles Id state This is the first time I frequented your web page and up to now I surprised with the research you made to make this actual post incredible Fantastic job

Somebody essentially help to make significantly articles Id state This is the first time I frequented your web page and up to now I surprised with the research you made to make this actual post incredible Fantastic job

My brother suggested I might like this blog He was totally right This post actually made my day You can not imagine simply how much time I had spent for this info Thanks

Thank you!!

Nice blog here Also your site loads up fast What host are you using Can I get your affiliate link to your host I wish my web site loaded up as quickly as yours lol